A reliability strategy: a new thinking paradigm is required

It’s an amazing fact that over 90% of the companies we come across have a reliability strategy based simply on servicing the components of the machine.

Why? Maintainers are excellent at repairing faults, rebuilding machines to a new standard and replacing components when they fail – that’s what they’ve been trained to do and not surprisingly, they do it well.

In continuous improvement circles, proponents of Total Productive Maintenance (TPM) often encourage this type of strategy leading to clean, shiny components and a boost to reliability but one that falls far short of potential.

So how to reach the potential?

A paradigm shift in thinking is required. Instead of leaving maintainers to focus on components while production managers focus on production speed, health and safety managers on keeping people safe and quality managers on product quality, an integrated approach is required.

So how do we integrate these desired outcomes?

The light-bulb moment is when you take time to understand the process, its functions and the standards of performance you require in terms of safety, productivity and quality. Then you realise that reliability is not about components but about maintaining these functions to the required standard of performance – standards of performance that are set by you, your customers, regulators and legislative requirements.

Another amazing fact – in the vast majority of cases, the team responsible for defining the maintenance strategy (the maintenance department or the original equipment manufacturer) does not have a full understanding of the functions and standards of performance required from the process. Hence why most reliability strategies fall well short of their potential.

Accepting this paradigm shift in thinking opens the door to an integrated approach to redefining the requirements to maintain the process operating to the required standards. It’s an integrated approach that requires the involvement of all business functions representing safety, quality, production and maintenance.

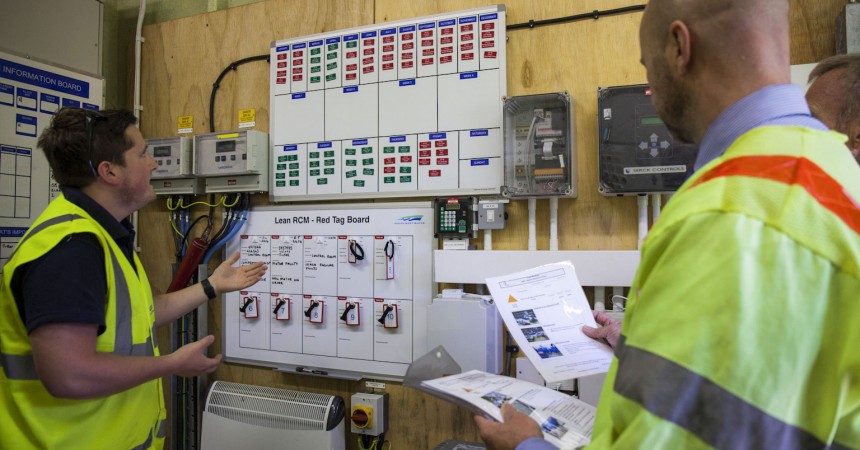

That’s exactly what Lean RCM does. It recognises that reliability is rarely to do with components and much more to do with maintaining the processes operating safely to supply customers with the product they want, when they want it, at the quality they expect.

Having a qualification in Lean RCM demonstrates an understanding of this different approach to reliability. That you’ve been through that light-bulb moment. At the highest level of the qualification; Lean RCM Facilitators – transform the approach to reliability allowing customers to reach the full potential other approaches do not achieve.

Share: