Visual is best. No training required

Share: What a simple LEAN way to help the novice commuter (me) navigate through the heaving crowds. Problem: How do I get from an […]

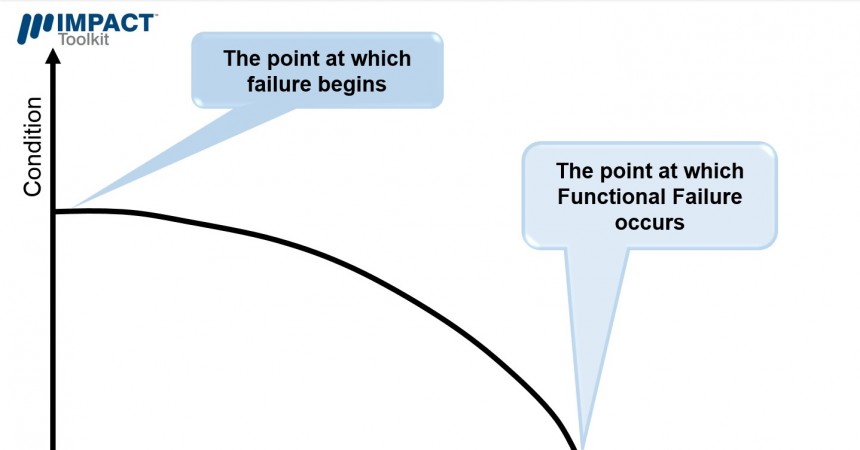

Read moreZero failures is not a myth it’s a reality if you Design for Reliability

Share: The reliability of your process is determined before it even arrives on the factory floor and not by the quality of your maintenance manager […]

Read moreHow to Sustain Lean Implementation

Share: I was in a conversation with a customer recently about Lean. My customer asked the question: What Lean tools should I learn to […]

Read moreScheduling tasks that add value

Share: Today was the climax of 3 months work coaching a team through a Lean RCM Masterclass in Lean Reliability Centred Maintenance. It was […]

Read moreToo much ‘Fat’ in your business?

Share: It is a simple analogy, but one that really helps focus the mind. Is your business fit? Is it agile? Or does it […]

Read moreEliminating waste … Learning to see

Share: To be Lean you have to be able to eliminate the waste from your process. To be able to eliminate the waste you […]

Read moreThe Chalk Circle

Share: The power of Gemba is easy to overlook or to forget about, or simply not have confidence when we watch out busy ant […]

Read moreLean RCM Improvement Journey

Share: Pedigree Credentials “It is a journey. And only by involving the people in this journey will you achieve ownership and long-term sustainable results” What […]

Read moreHow Root Cause Analysis Can Help You Predict the Future

Share: I am often asked “Is the right strategy to start applying root cause analysis at the beginning of an improvement journey and get […]

Read moreThe application of Lean RCM to Facilities Management & maintenance of public institutions

Share: It’s the generation of cuts. Tax credits, pensions, budgets, deficits; all being cut. Interesting to reflect how most of these cuts seem to apply […]

Read more