Facilities Management – Early adopters of Lean RCM will be the winners

Facilities Management providers have yet to adopt a Lean RCM approach and are missing a golden opportunity to double their profit margins. However not all the facilities management companies can realise this opportunity as only those first past the post will get a share of the benefits.

Traditionally, facilities management contractors provide quotations for maintaining the building services assets of a building or factory such as heating and ventilation, water distribution, waste, lighting, etc based on time and materials required to perform the maintenance. This standard approach is a component-upwards strategy a usually based on best practice guides such as the CIBSE guide.

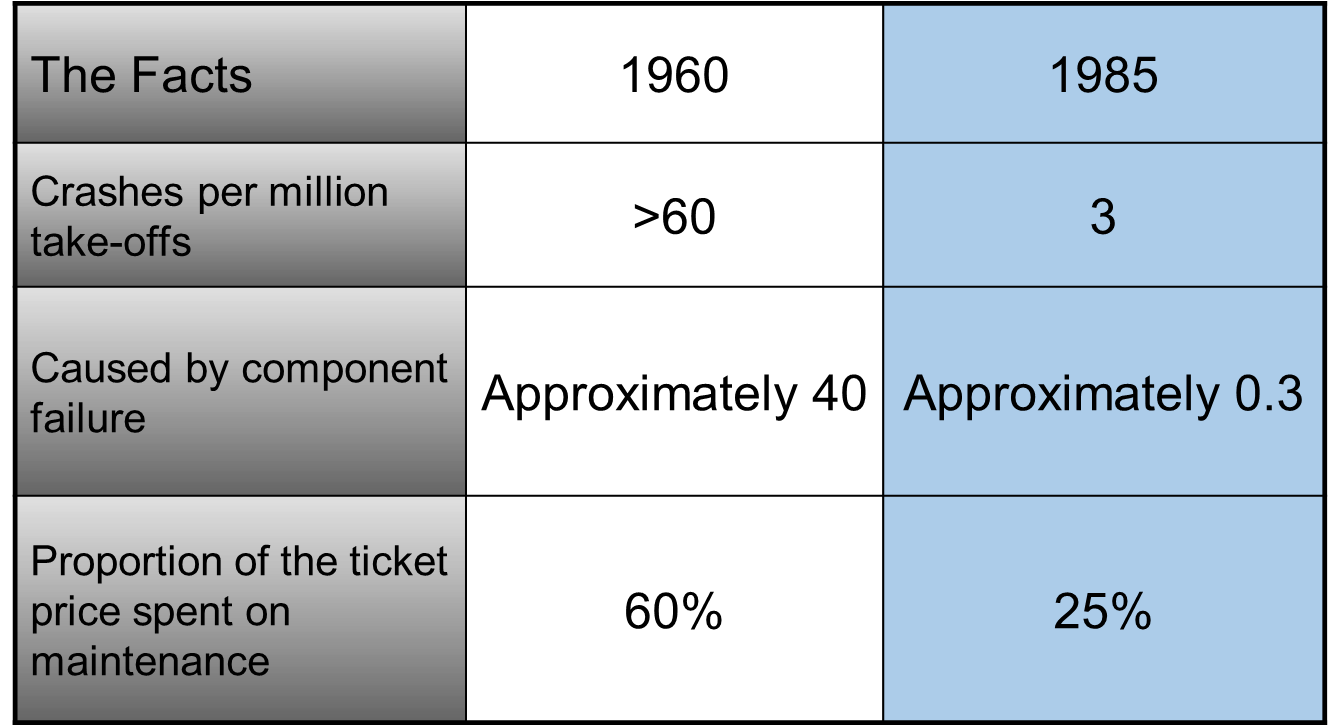

Lean RCM, the standard for aircraft maintenance-the undisputed champion of reliability, starts with the equipment functions and standards of performance and only considers the components where this is necessary. In the aircraft industry, the introduction of RCM eliminated the vast majority of the previously scheduled maintenance tasks which were either adding no value or, much worse, introducing faults to the system. RCM was introduced in the aircraft industry in 1978 and the results speak for themselves.

The Facilities Management industry has been very slow to adopt or even accept the lessons learned in the aircraft industry. There is a good reason for this. It goes against the grain to actively seek to reduce your turnover in the short term which is exactly what Lean RCM would do for a facilities management contract of who chose to accept this approach. However, in the longer term the early adopters of Lean RCM in the facilities management industry will be the winners as they will be sold clearly ahead of their competitors that will gain a much bigger share of the market.

Perhaps there will come a time when it is a requirement for all facilities management contractors to apply the methodology of Lean RCM just as it is an operating licence requirement for all aircraft operators have a Lean RCM strategy.

So what are the benefits for any facilities management contractors who are willing to buck the trend and be leaders in the marketplace by adopting this technique?

Simple, use Lean RCM as the backbone of all services contracts which will allow profit margins to double, give better performance in the eyes of the customer and reduce unnecessary work. In the short term this will mean reduced turnover but in the longer term, the significant point of difference when compared to the other traditional based facilities management contractors will lead to a much bigger share of the market.

The table below gives a simple example of how to double profit margin whilst keeping the customer happy using Lean RCM.

| Method | Total cost of providing the service to the customer | Profit margin | Final price to the customer | Customer benefits |

|---|---|---|---|---|

| Traditional approach based on time and materials | 100 | 20% | 120 | Service level agreement met |

| Lean RCM approach | 50 | 40% | 70 | Service level agreement exceeded Facilities management contract as additional value to customer’s business |

In case you are wondering how we are so sure that this will eliminate 50% of the standard maintenance activities, we have the evidence. Time and time again application of Lean RCM reduces the amount of scheduled maintenance required by at least 50% and often as high as 70 or 80%. And, gives better reliability so it’s a win win situation.

So what’s next? As general awareness of the benefits of Lean RCM grows it is only a matter of time before the customers of facilities management companies start to demand this approach. How can we be so sure? We are already involved in a pilot program with a large multinational food manufacturer who has asked their facilities management contractor (one of the major players) to participate in a Lean RCM program. Despite some initial resistance, they are now on board but will need to keep focused on the longer term benefits as I’ve already mentioned, in the short term it will cut the maintenance requirements significantly.

Share: